|

Construction of Wairoa Dam

Wairoa Dam is a water supply dam in

the Otau Valley in the Hunua Ranges southeast of Auckland. It was built by

the Auckland Regional Authority and is now owned by its successor

Watercare Services Ltd.

History

Design Construction

Photos:

Tunneling

Dam Construction Valve

Tower Valve

Tower Bridge Delivery

Pipeline Finishing

Spillway Spillway

Model Lake Clearance

Moumoukai

|

A modern view of Wairoa Dam - Simon Lieschke

|

It was built in the early 1970's. The series of

photographs on this

site were

taken by the site staff at the time of construction. This website was

created by Garry Law who was one of the designers of the dam and worked

on site during the construction as part of the resident engineer's staff

while living at Moumoukai. He took some of the photos. The site camera

was a Canon Canonet rangefinder. The colour images here were taken by

the author as slides, on a Petri

7s rangefinder camera.

Thanks to Graeme Doherty and

Huia Mitchell for contributions.

| Wairoa Dam |

| Completed: 1975 |

| Lake area: 98

hectares |

| Capacity: 11.6

Gigalitres |

| Catchment

area:

1303 hectares |

| Dam

height:

47m |

| Dam

type:

Earth fill |

| Fill

volume:

685,000 m3 |

| Service spillway:

Bellmouth |

| Spillway

capacity

122 m3/s |

| Mean

yield:

32Ml/d |

| Contractor:

Downers |

| Contractor's

Engineer: George Wyman |

| Cost:

$3.9M |

There are four other dams in the ranges.

The site is open to the public in daylight hours. there are toilet

facilities for visitors. Unfortunately the bronze plaque that

marked the opening by Authority Chairman Tom Pearce on May 23, 1975 and recorded some information on the dam construction

has been removed by vandals.

The brochure produced for the opening

(thumbnails).

|

Contact:

Comments and contributions are welcome!

|

The Dam on Google Maps:

View Wairoa Dam in a larger map

A Little History:

Wairoa Dam was originally intended to be the fourth dam in the

ranges. The tunnel system to carry water to Ardmore Treatment Plant

and thus to the city had gone past the site connecting through to the second

built dam, Upper Mangatawhiri. A flow gauging and interim intake weir was

built above the proposed Wairoa Dam site and an interim run of stream supply

commenced from that in 1960. The Mangatangi dam site had a similar weir

and interim supply. Mangatangi dam was supposed to be next in the

sequence and work commenced on that, but contractual difficulties with

the construction of the diversion tunnel had it running behind schedule.

In a period where demand growth averaged over 4% per annum this

presented a risk to Auckland's water supply. Consequently on the

suggestion of long term resident engineer Eric Scanlen, Wairoa Dam was

advanced in the sequence and was built in parallel to Mangatangi,

entering service two years earlier than the completion of

Mangatangi. The other sites mentioned here are shown on the Google map

below.

Design:

|

Plan and section - thumbnail - the

information on the control valve chamber is incorrect.

|

The design was lead by the ARA water department design engineer, Don

Wilson. Other contributors were Eric Scanlen (hydrology, general

diversion and spillway arrangement), John Crabtree (spillway

preliminary, site investigation), Garry Law

(spillway and delivery system), Graeme Barnard (geotechnical) and Remi

Gobet (structures). All calculations were by hand assisted only by an

early electronic calculator. Computer aided design in civil engineering

was then in its infancy.

Construction:

Work commenced on the diversion tunnel utilising a labour-only form

of contract that had been much used for tunneling work by the Regional

Authority and its preceding organisations. The Authority provided all

plant and materials for the tunnel. A concrete batching plant was established at the

site. John Crabtree was the staff engineer in charge of this work,

reporting to Eric Scanlen. The main work was let by competitive tender

to Downer and Co through a conventional construction contract. The delivery pipeline from the tunnel mouth to the

supply tunnels was laid by an ARA pipe gang. There was an on-site

earthworks control laboratory.

While building the dam the ARA staff also did a site investigation

for Lower Mangatawhiri Dam (never built) and undertook the Ardmore

supply tunnel duplication.

| ARA Team: |

| Resident

Engineer:

Eric Scanlen |

| Earthworks Engineer:

John Crabtree |

| Structures

Engineer: Garry Law |

| Surveyor:

Phil Salmon |

| Laboratory Technician: Peter

Thomas |

| Assistant

Engineer

Neil Boys |

| Survey

Assistant

Chuck Bird |

| Construction Sequence |

|

| Tunnels /

spillway / intake |

Dam |

|

The diversion tunnel was driven including the spillway

up to the elbow but not including the shaft.

|

|

|

Tunnel lining was completed, not including the elbow

|

|

|

The trench for the delivery pipe was excavated in the

tunnel floor and the pipe laid in it and concreted in - integrally with

the tunnel floor.

|

Site stripping

commenced |

|

The valve tower base was built (tendon anchored

into the rock)

|

The temporary

supply was diverted through the supply pipe as far as the

downstream portal

|

|

The stream was diverted through the diversion

tunnel

|

| - |

Site stripping completed |

| Spillway shaft excavated from

above |

Dam earthworks |

| Liner for upper spillway shaft set

into fill |

| Valve tower slipformed |

| Valve tower bridge completed |

| Spillway elbow lining, shaft

lining and bellmouth crest completed. |

| Bottom outlet pipe put in place,

weir off take diverted through it, tunnel plug shuttered up and

poured |

|

| Valve tower pipework completed,

supply pipeline completed |

|

| Bottom outlet gate valve closed -

lake filling commenced |

|

| Bottom outlet discharge valve

installed |

|

| Tunnel junction training wall and

spillway stilling basin

constructed |

|

The pictures following are all thumbnails.

|

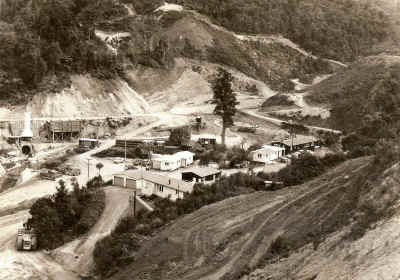

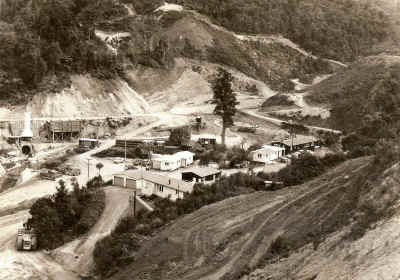

Stripping of the dam site has commenced. Pipe for the supply

line stacked in the middle distance over the stream bridge. The

stream diversion was not yet in place. |

|

The stream diverted and the dam part finished - the valve tower at full height but

with no bridge. |

|

The dam a little higher and the bridge to the valve tower

under construction - the aggregate bins for the tunnel concrete

lining have gone. The tree in the center has had too much root

disturbance and is near death. |

|

The dam nearing full height in the second earthworks season |

|

West abutment from the east - during site investigation |

Tunneling:

|

Tunnel form at the downstream portal. The cement silo is over

the portal, the concrete mixer below that which discharged into

the concrete carriage vehicle in the tunnel. The mixer was fed

from a trolley mounted weigh hopper discharging onto a belt. The

three aggregate and sand hoppers are above. The central building

is the compressor shed. The air extract fan pipe can be seen

left of the portal, but has been disconnected. |

|

Tunnelers - John Crabtree second from left. |

|

Damaged photo of the tunnel junction form |

|

Shifting the tunnel form |

|

Taking pipe into the tunnel - taken from the tunnel portal -

the form is parked to the right |

|

Placing pipe in the tunnel floor. |

Dam

Construction:

|

Site stripping commencing - photo from upstream. The miners

adit into the manganiferous rock can be seen at the right. |

|

Later in site stripping. |

|

Downstream shoulder stripping |

|

Core trench, covered drains from springs to the

pump well |

|

Spring pump well |

|

Right abutment shaping |

|

Grout pipes to close pump wells |

|

Filling |

|

Down stream shoulder filling |

|

|

|

Piezometer tubes |

|

Dam site Panorama |

|

General view looking downstream - early in the fill placement |

|

Compacting the filter drain - constructed by excavating a

trench through fill down to the last lift. |

|

Filter drain construction |

|

Filter drain construction with core placement

upstream |

|

Filter drain construction - spillway shaft to the

left |

|

The west abutment - soft sensitive alluvial

material required stripping her to get to competent rock and

weathered rock |

Valve Tower:

|

Tunnel form being positioned at the upstream portal. The

inverted siphon of the interim supply pipe can be seen and the

under-floor permanent supply pipe |

|

Link section from the upstream portal to the valve tower.

Inverted siphon on temporary supply pipe goes under. |

|

Reinforcing tieing for the valve tower base |

|

Shuttering for the valve tower base. |

|

Rock anchor tendons. |

|

Anchoring, pre-diversion. The weir supply pipe diverted

into the tunnel |

|

Slipforming the valve tower underway |

|

Valve tower top |

|

Installing an intake gate valve |

|

Concreting in an intake in the valve tower |

|

Fixing the lake level markers to the valve tower |

|

The bottom outlet pipe in place. |

|

Pouring the tunnel plug in the valve tower base. |

|

About to close the bottom outlet gate valve - from the left

Bruce Smithson, Don Wilson, John Crabtree, ?Keith Hay, Fergie

Schiska, ?(ARA photographer), ?. |

|

The bottom outlet closed, Eric Scanlen facing the camera,

George Wyman on the right on the platform. |

|

Installing the discharge valve on the bottom outlet. |

Valve

Tower Bridge:

|

Foundations for the bridge pier |

|

Pier bases |

|

Pier construction from the tower. |

|

Pier construction |

|

Pier construction |

|

Concrete pour for the pier |

|

Launch beam |

|

Delivery of a Tee beam for the valve tower bridge |

|

Ditto |

|

First beam ready to launch |

|

First beam about to be lowered |

|

Ditto |

|

Third beam |

|

Last beam in place |

Delivery

pipeline:

|

Delivery pipe for the downstream portal to the

control structure under way |

|

Supply pipe being laid |

|

Control valve chamber inner form. Link structure

between the two tunnels in the background. Damaged photo. |

|

Control valve being installed, pipe to right is

the overflow for an emergency drawdown. The valve has special

porting allowing fine control over part of the travel and

opening a large port area over the latter part for emergency

drawdown.. |

|

Completed control structure |

Finishing:

Spillway:

|

Spillway elbow shutter - in two halves second in

back right. |

|

Spillway outside former |

|

Stilling basin excavation |

|

Stilling basin excavation |

|

Stilling basin construction |

Spillway

model:

|

The 1:40 scale hydraulic model of the spillway stilling basin

running at full capacity.

The model was built by the Authority staff and run at the

Auckland University Engineering School hydraulics lab. It was

used to confirm the bellmouth approach and fins were sufficient

to suppress vortexing in the down shaft, to check the choke size

needed at the bottom of the shaft, the pressures in the shaft,

the diversion tunnel transition, and the stilling basin form.

A large number of varieties of the stilling basin were tried,

mainly to get the teeth positioning and sizes right to control

the position of the hydraulic jump.

The shaft pressure checks were important as the transition

from the bellmouth to the vertical shaft was kept short to limit

the amount of double curvature shuttering that needed to be

built. With this a length of the shaft would run below

atmospheric pressure. If pushed too far the pressure would fall

to full vacuum and the flow might separate. The model confirmed

pressures stayed above full vacuum.

The choke at the shaft base limits the flow so the exit tunnel remains as free

surface flow. Otherwise the whole tunnel might fill expelling

air and run as a full pipe, increasing the flow beyond the

stilling basin capacity.

|

The Lake:

There were small areas of original bush in the lake area but most of

it had been cleared for farming between the wars. After the Council had

bought it for catchment land it had reverted to scrub - some of it high

kanuka by the 1970s. The vegetation had to be removed from the lake area

for water quality

reasons. The task was performed by staff. The initial task was cutting a

waterline road then felling the vegetation within the lake area and

burning it. The burning was done in stages. One fire got out of control

and burned a small area of bush above the waterline.

|